# Beyond the Joystick: Why Medtronic’s Hugo is a Platform for the Future of Surgery

The modern operating room is rapidly transforming from a purely human-centric domain into a complex, data-rich ecosystem. For years, the conversation around robotic-assisted surgery (RAS) has been dominated by a single, monolithic player. But the landscape is changing. Medtronic’s Hugo RAS system isn’t just another competitor; it represents a fundamental shift in design philosophy and, more importantly, a powerful platform for the next generation of AI-driven surgical intelligence.

The recent news that Medtronic received a CE Mark for integrating its Ligasure vessel sealing technology with the Hugo system is more than just a product line extension. For those of us in the AI and robotics space, this is a clear signal of the industry’s trajectory: moving from teleoperation to intelligent instrumentation.

—

### Main Analysis: Modularity, Data, and the Intelligent End-Effector

To understand the significance of Hugo, we need to look at three core technological pillars: its architecture, its instrumentation, and its potential as a data pipeline.

**1. A Modular, Microservices-Style Architecture**

Unlike the single-cart systems that defined the first wave of surgical robotics, Hugo is inherently modular. Its individual robotic arm carts can be wheeled in and positioned as needed. From a purely physical standpoint, this offers hospitals flexibility in OR setup and a potentially smaller footprint.

From a technology perspective, however, this modularity is analogous to the shift from monolithic software to a microservices architecture. Each arm is a discrete, independent unit communicating within a larger system. This design offers several advantages:

* **Scalability:** Hospitals can start with a smaller number of arms and scale their investment as needed.

* **Resilience:** A potential issue with one component is less likely to bring the entire system offline.

* **Adaptability:** It opens the door for future integration of specialized components—perhaps a dedicated imaging arm, a diagnostic probe, or other AI-powered tools—without requiring a complete system overhaul.

This flexible, distributed hardware model is the ideal foundation for an evolving software and AI platform.

**2. The Ligasure Integration: From Tool to Intelligent Node**

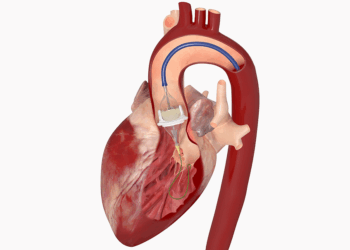

The real game-changer lies in the integration of advanced instruments. Ligasure isn’t just a robotic scissor; it’s a sophisticated energy device that monitors tissue impedance in real-time to deliver the precise amount of energy needed to seal a blood vessel, minimizing thermal spread.

When you connect an instrument like this to a robotic platform, you create a powerful feedback loop. The robot is no longer just a “dumb” holder for a tool, translating the surgeon’s hand movements with precision. It becomes a conduit for critical, real-time data from the surgical site itself.

This is where the AI potential explodes. We can now envision a system where:

* **Machine learning models** analyze the data stream from the Ligasure’s tip to provide real-time feedback to the surgeon on tissue type and vessel quality.

* **Computer vision** from the system’s endoscope is correlated with the instrument’s energy delivery, learning to identify anatomical structures and create “no-fly zones” to prevent inadvertent damage.

* **The system can offer intelligent assistance**, such as automatically modulating energy levels based on its analysis, ensuring a perfect vessel seal with minimal surgeon intervention.

This transforms the end-effector from a simple tool into an intelligent, data-gathering node at the point of patient contact.

**3. The Data Ecosystem: Fueling the Next Wave of Autonomy**

Every procedure performed with the Hugo system is a massive data-generation event. We’re not just talking about video. We’re talking about synchronized telemetry from every joint in the robotic arms, force feedback data, instrument usage logs, and surgeon interaction patterns.

The impending U.S. FDA approval will be a critical milestone not just for market access, but for data access. The US market will provide an enormous and diverse dataset that is the essential fuel for training the next generation of surgical AI. This data can be used to:

* **Benchmark performance:** Objectively analyze surgical techniques to identify best practices.

* **Develop automated sub-routines:** Train models to perform repetitive tasks like suturing or dissection with superhuman consistency.

* **Create predictive models:** Use pre-operative scans and real-time data to anticipate challenges and guide the surgical strategy.

—

### Conclusion: The Race is for the Platform, Not Just the Robot

Medtronic’s progress with the Hugo RAS system underscores a crucial truth: the future of robotic surgery isn’t just about building a better robot. It’s about building a better *platform*. The winning systems will be those that are open, modular, and designed from the ground up to integrate intelligent tools and leverage the resulting data streams.

The recent CE Mark for the Ligasure integration is a significant step in this direction. It proves out the model of a smart, data-enabled instrument working in concert with a flexible robotic framework. As Hugo moves towards FDA approval and wider adoption, its true value won’t just be in assisting surgeons, but in building the vast data foundation upon which the future of AI-powered, and eventually semi-autonomous, surgery will be built. The race is on, and the battlefield is data.

This post is based on the original article at https://www.bioworld.com/articles/723206-medtronic-expects-its-hugo-robotic-system-set-to-drive-future-growth.